The carbon black production plant (machine for the production carbon, electro-arc plant or electro-arc synthesis plant) is designed for cyclic production of carbon black with the content of the main substance – pure carbon (black powder), depending on the specified production conditions and installation settings.

The installation is a complex of standard and non-standard equipment included in the General cycle of the technological process of arc combustion in an atmosphere of inert gas – helium or argon.

CATALOG OF EQUIPMENT FOR THE PRODUCTION OF CARBON BLACK

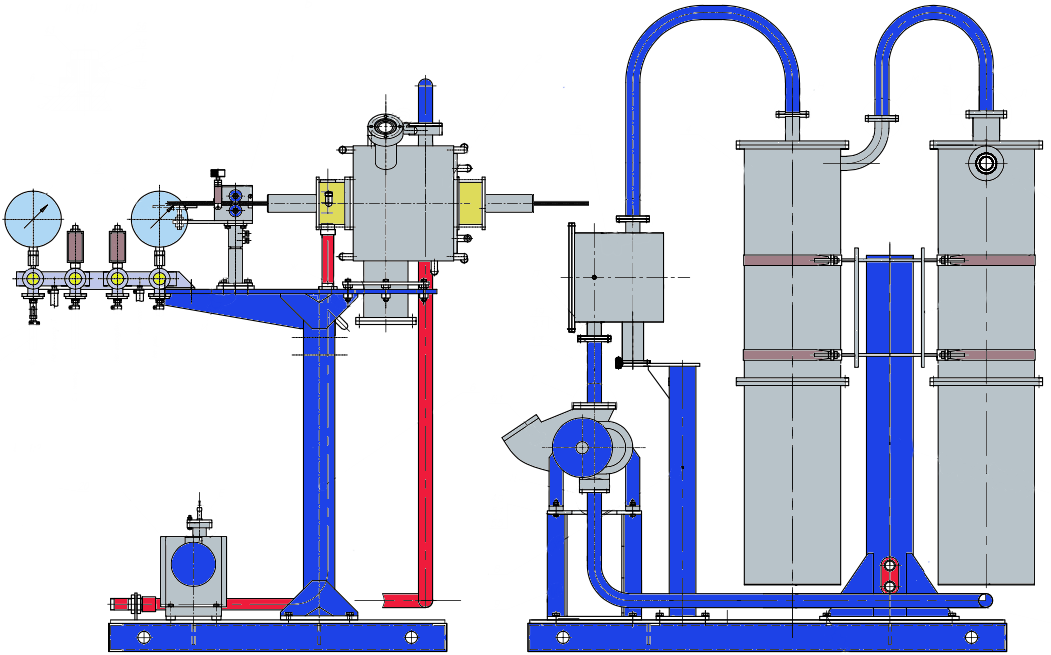

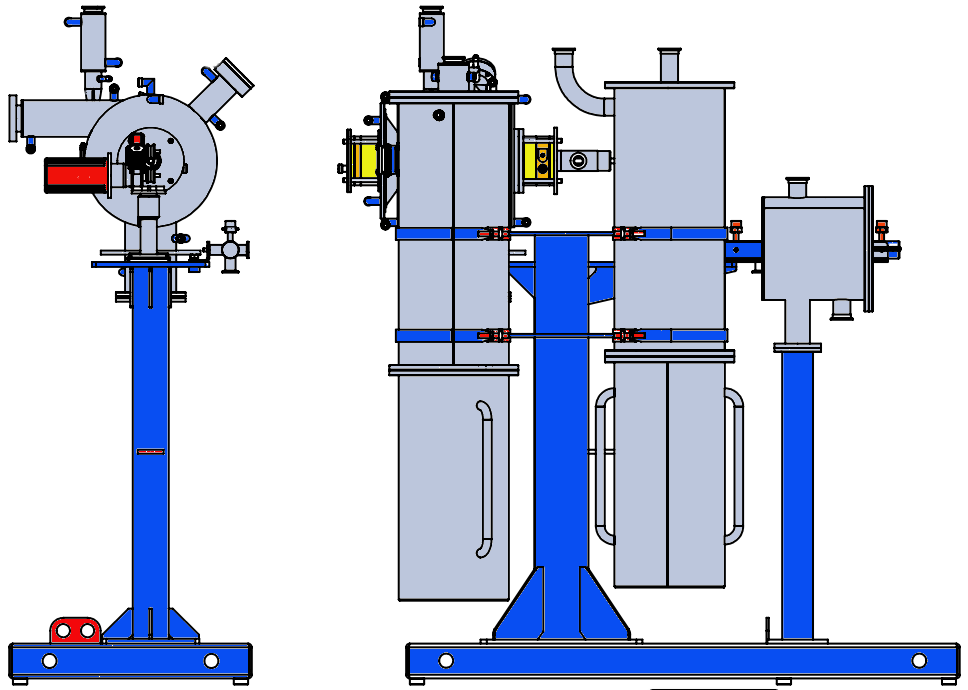

DESCRIPTION OF THE MAIN ELEMENTS OF FULLERENE SOOT MACHINES

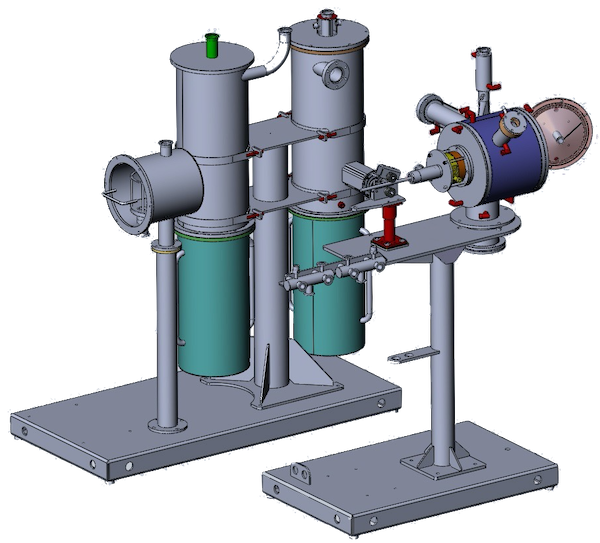

FSM-500

FSM-800

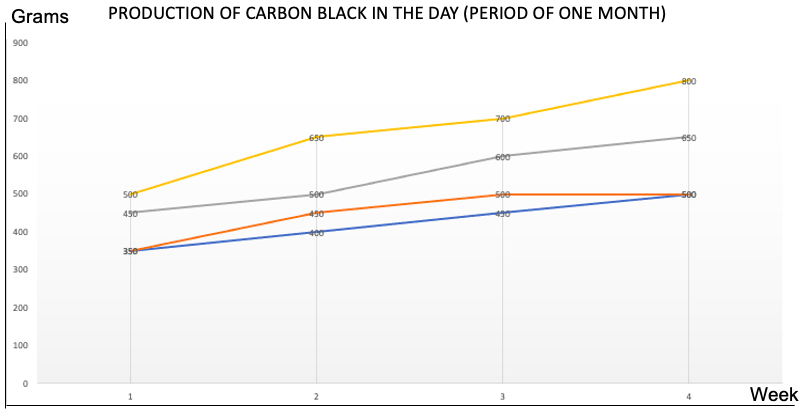

The dynamics of increasing the daily volume of carbon black production directly depends on the stable operation of the FSM and compliance with the technical operating conditions. The volume of carbon black production per day, which is achieved with the continuous operation of the plants for one month, shows the maximum volume of product production in about 3-4 weeks.

COMPARISON OF MACHINES

The graph shows a comparison of the FSM performance of different models:

- indicators of the FSM 500 complex

- indicators of the FSM 500 VS complex

- indicators of the FSM 650 complex

- indicators of the FSM 800 complex

- indicators of the FSM 500 VS complex

- indicators of the FSM 650 complex

- indicators of the FSM 800 complex

Each type of plant is designed for specific production purposes or specialized production, namely, the production of modifiers, fillers, nanomaterials and other products.

The small daily volume of carbon black powder production at the FSM 500 / 500 VS complexes is not an indicator of "limited technology", on the contrary, in some types of production, these machines are highly cost - effective and efficient.

The small daily volume of carbon black powder production at the FSM 500 / 500 VS complexes is not an indicator of "limited technology", on the contrary, in some types of production, these machines are highly cost - effective and efficient.

FSM LC - LABORATORY C

Laboratory complex for limited synthesis of carbon black – FSM LC.

The performance of this complex and the period of its cyclic operation are designed for the synthesis of a small volume of product – up to 200 grams of carbon black powder in 4 hour.

The performance of this complex and the period of its cyclic operation are designed for the synthesis of a small volume of product – up to 200 grams of carbon black powder in 4 hour.

LABORATORY

FULLERENE SOOT

FULLERENE SOOT

COMPARISON OF FSM MACHINES

NAME / ELEMENTS

FSM-500

FSM-500 VS

FSM-650

FSM-800

Reactor chamber

Lid of the reactor

Lid hinge of the containment vessel

Anode current collector

Cathode current collector

Anode/cathode internal insulator

Anode/cathode external insulator

Current collector flange-anode

Current collector flange-cathode

Current Collector Crown Stud Anode / Cathode

Electrode insertion chamber

Current collector lower dies

Current collector upper dies

Electrode insertion chamber Inserts

Ebonite

Ebonite

Polymer

Polymer

Centralizer of the input chamber

Ebonite

Ebonite

Polymer

Polymer

Seals of the input chamber VITON

Centralizers of the input chamber, metal

Insertion chamber nuts

Reactor chamber collector cover

Window Flange

Reactor chamber glass

Tank-container №1

Handle container tank holder

Housing of the tank-container (refrigerated)

Cover-flange (with cooled pipe)

Tank-container №2

Handle container tank holder

Collector housing (uncooled)

Coarse filter frame

Coarse filter

Telescopic stand

Rack Insulator

Feeding device shelf

Gears of the feed mechanism

Feed rollers-polyurethane

Stepper motor crown

Stepper motor (4.2 А / 6.0 А)

4.2 А

4.2 А

6.0 А

6.0 А

Gas collector shelf

Gas collector

Vacuum gauge pointer

Mechanical vacuum gauge

Mechanical vacuum gauge

Digital vacuum gauge

Pump-blower 80 m3/h

Rotary pump 20 m3/h

Rotary pump 90 m3/h

Vacuum station 180 m3/h

Vacuum receiver 500 liters

High-vacuum gate valve

Pressure boosting pump

1.8 Atm

1.8 Atm

2.8 Atm

3.3 Atm

Comparison of sets of installations for the production of fullerene soot is given in general form. Each entity using this type of equipment collects specific models for its own goals and objectives, and in the process selects individual blocks of both standard and auxiliary equipment.

In general, a set of options and mechanisms are available for each type of equipment, which may not be included in this list, but which allow you to achieve optimal performance of the FSM machine in accordance with specific selection criteria and the task.

In general, a set of options and mechanisms are available for each type of equipment, which may not be included in this list, but which allow you to achieve optimal performance of the FSM machine in accordance with specific selection criteria and the task.

The information provided on this page is not commercial! All data are of a technical and general informational nature!