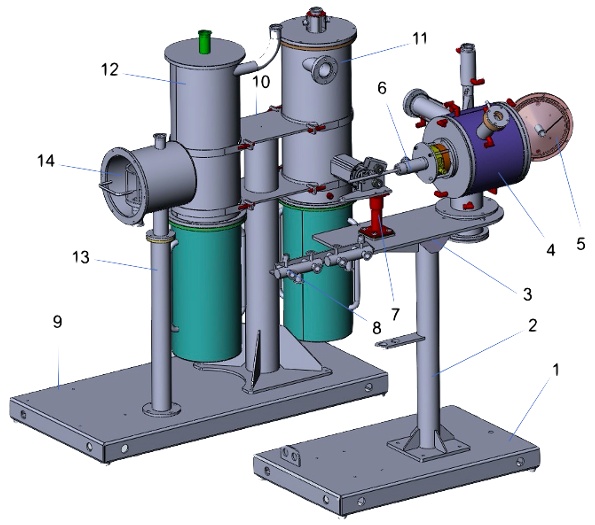

The metal frame is almost completely made of stainless steel, to prevent corrosion of the surfaces of the cowling of the cooling system of the installation and to achieve the best qualitative and quantitative indicators in the process of obtaining the main product - carbon black.

COMPONENTS OF METAL FRAME

1. Reactor chamber base

2. Reactor chamber shelf stand

3. Reactor chamber shelf

4. Reactor chamber

5. Lid of Reactor chamber

6. Electrode insertion chamber

7. Rod feed (movement) machine

2. Reactor chamber shelf stand

3. Reactor chamber shelf

4. Reactor chamber

5. Lid of Reactor chamber

6. Electrode insertion chamber

7. Rod feed (movement) machine

8. Gas distribution ramp

9. The base of tank-containers unit

10. Stand of tank-containers

11. Tank-container № 1 with cooling system

12. Tank-container № 2 with filtration system

13. Fine filter stand

14. Fine filter

9. The base of tank-containers unit

10. Stand of tank-containers

11. Tank-container № 1 with cooling system

12. Tank-container № 2 with filtration system

13. Fine filter stand

14. Fine filter

The bases of the machine FSM (1) and (9) is made in a independent format for the convenience of placing the equipment in the area of its subsequent operation, as well as for more convenient technological maintenance both during the immediate operation of the installation, and during unloading and launch.

The metal frame consists of the given below structural elements:

The shelf stand (2) is bolted with 4 M10 bolts to the base (1) for subsequent mounting of the camera reactor and additional mounting mechanisms. The reactor chamber (4), with the help of 4 adjustment bolts M10 screwed into the shelf (3), is set to a horizontal level relative to the shelf itself (3) and the collection (tank-container № 1) (11). A vacuum inlet (6) is mounted to the reactor chamber (4), on the side of the anode electrode, through which a graphite electrode is fed during the operation of the unit. On the back (front) side of the reactor chamber (4), the lid of the chamber (5) is hung, which is a sluice that allows primary and secondary cleaning of the reactor chamber, as well as carry out normal procedure maintenance work on the graphite electrode input unit and the cathode unit. Additionally a rod feed system (7) and a gas distribution ramp (8) are mounted on the shelf (3), which are insulated through rubber or textolite insulators to the shelf (3).

The stand of tank-containers (10) and the fine filter stand (13) are screwed to the base (9) of the installation for the subsequent installation of the mounted collectors (tank-containers) (11) and (12), using 4 M10 bolts on each stands. The collections (tank-containers) (11) and (12) are fixed to the stand (10); IMPORTANT! the collection (11) is centered relative to the outlet pipe of the reactor chamber (4). The final mounting of the collection (11) takes place after the connecting flange of the chamber (4) and the collection (11) is fully tightened. The filter (14) is installed on the stand filter (13) at the very end, to compliance with dimensions of the pumping equipment.

The stand of tank-containers (10) and the fine filter stand (13) are screwed to the base (9) of the installation for the subsequent installation of the mounted collectors (tank-containers) (11) and (12), using 4 M10 bolts on each stands. The collections (tank-containers) (11) and (12) are fixed to the stand (10); IMPORTANT! the collection (11) is centered relative to the outlet pipe of the reactor chamber (4). The final mounting of the collection (11) takes place after the connecting flange of the chamber (4) and the collection (11) is fully tightened. The filter (14) is installed on the stand filter (13) at the very end, to compliance with dimensions of the pumping equipment.

DESCRIPTION