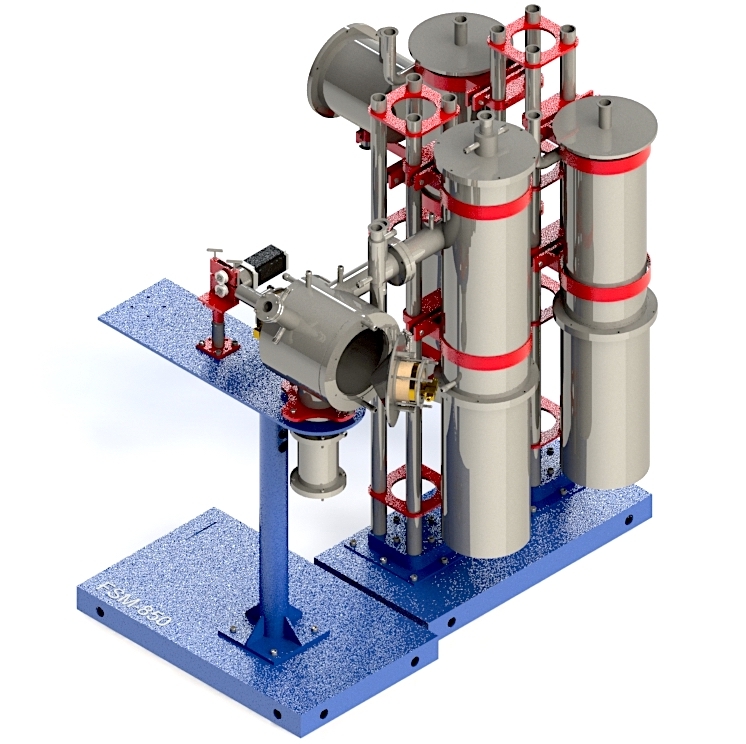

REACTOR FSM-800

FSM-800 characteristics:

Weight - 610 kg.

Assembled size - 1800x1900x2200 mm.

Electricity power - 23 kW.

Refrigerant volume - 1.5 cmh.

The volume of helium per cycle is 1.2-1.7 liters.

The amount of the product received per shift is 750-800 grams.

Weight - 610 kg.

Assembled size - 1800x1900x2200 mm.

Electricity power - 23 kW.

Refrigerant volume - 1.5 cmh.

The volume of helium per cycle is 1.2-1.7 liters.

The amount of the product received per shift is 750-800 grams.

Machine for the production of carbon black FSM-800.

It is a unique complex for the cyclic production of carbon black in an inert gas environment-helium or argon.

The capacity of the standard equipment of the FSM-800 installation is 750-800 grams of soot per day.

The continuous operation period of the unit is 23 hours.

The number of personnel involved in the production of carbon black – 2 operators.

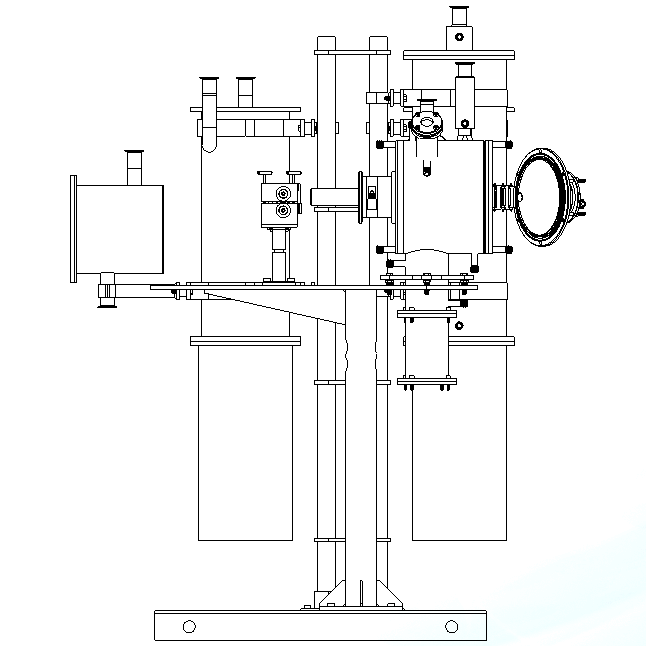

The control panel of the FSM-800 complex allows you to monitor the operation of the plant as a whole, to take readings of monitoring and metering devices, both at the stage of preparation of the production process, and during the process of soot production itself.

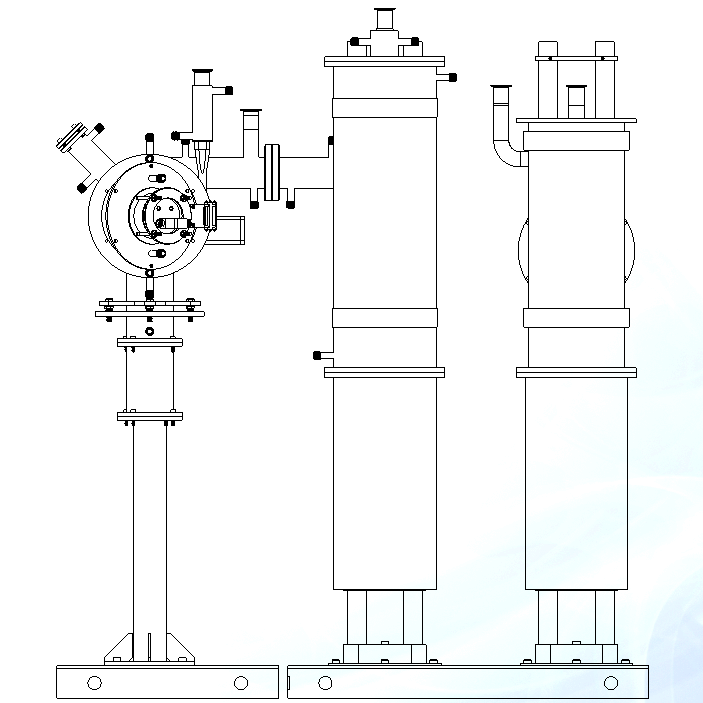

Pumping equipment has a number of protection elements that exclude the possibility of its failure, both at the stage of preparing the complex for operation, and during the production of carbon black. Three filters made of high-quality material exclude the ingress of fine carbon black into the working units of the pumps, which in turn preserves their reliability and resource efficiency.

The cooling system of the complex is provided with an additional pump for increasing the pressure in the refrigerant line-3.3 cubic meters / hour, which eliminates possible overheating of individual circuits of the complex and improves the quality of the production of carbon black, namely the main substance-nanomaterials. The basic version of the FSM-800 comes with an overheat protection system, an automatic polarity reversal system, and a vacuum station. The vacuum station allows you to prepare the complex for operation four times faster than the FSM-500 model.

Arc control system and quantitative adjustment of the ampere characteristic, also executed in the basic version of the complex.

The unit is made of high-quality processed stainless steel with a sheet thickness of 2.1 to 2.5 mm. (depending on the design element), in compliance with the basic conditions for the production of equipment operating under pressure. Each piece of equipment is tested for the average vacuum level and refrigerant pressure in cooling systems up to 3.5 Atm.

The technological features of the installation, as an option, suggest the possibility of removing the control panel from the carbon black production area, by installing a video surveillance system and remote control of the electrode supply system.

Also, the FSM-800 version of the machine can be equipped with an automatic rod feed system, which eliminates the" human factor " - operator error, and accelerates the process of carbon black production.

Pumping equipment has a number of protection elements that exclude the possibility of its failure, both at the stage of preparing the complex for operation, and during the production of carbon black. Three filters made of high-quality material exclude the ingress of fine carbon black into the working units of the pumps, which in turn preserves their reliability and resource efficiency.

The cooling system of the complex is provided with an additional pump for increasing the pressure in the refrigerant line-3.3 cubic meters / hour, which eliminates possible overheating of individual circuits of the complex and improves the quality of the production of carbon black, namely the main substance-nanomaterials. The basic version of the FSM-800 comes with an overheat protection system, an automatic polarity reversal system, and a vacuum station. The vacuum station allows you to prepare the complex for operation four times faster than the FSM-500 model.

Arc control system and quantitative adjustment of the ampere characteristic, also executed in the basic version of the complex.

The unit is made of high-quality processed stainless steel with a sheet thickness of 2.1 to 2.5 mm. (depending on the design element), in compliance with the basic conditions for the production of equipment operating under pressure. Each piece of equipment is tested for the average vacuum level and refrigerant pressure in cooling systems up to 3.5 Atm.

The technological features of the installation, as an option, suggest the possibility of removing the control panel from the carbon black production area, by installing a video surveillance system and remote control of the electrode supply system.

Also, the FSM-800 version of the machine can be equipped with an automatic rod feed system, which eliminates the" human factor " - operator error, and accelerates the process of carbon black production.

BRIEF DESCRIPTION OF THE FSM-800 MACHINE

Processability

Easy maintenance

Reliability

Product quality

Production Speed

Easy maintenance

Reliability

Product quality

Production Speed

MODEL COMPARISON

The FSM-800 technology complex was developed in 2016 together with specialists from one of Russia's leading innovation clusters. It is high-performance and multifunctional, both in terms of the production of carbon black, and by – products-nanomaterials, which are an integral part of the main composition of soot.

A well-developed system of gas-dynamic flows, their cooling and product distribution system, allow for the production of up to 800 grams of carbon black enriched with ultrafine nanomaterials within 22-23 hours. Partial automation of the production process, intuitive management of the complex, subject to the basic principles of the technical process of carbon black production, allow you to produce high-quality carbon black with a base substance content of at least 9-10%.

A well-developed system of gas-dynamic flows, their cooling and product distribution system, allow for the production of up to 800 grams of carbon black enriched with ultrafine nanomaterials within 22-23 hours. Partial automation of the production process, intuitive management of the complex, subject to the basic principles of the technical process of carbon black production, allow you to produce high-quality carbon black with a base substance content of at least 9-10%.