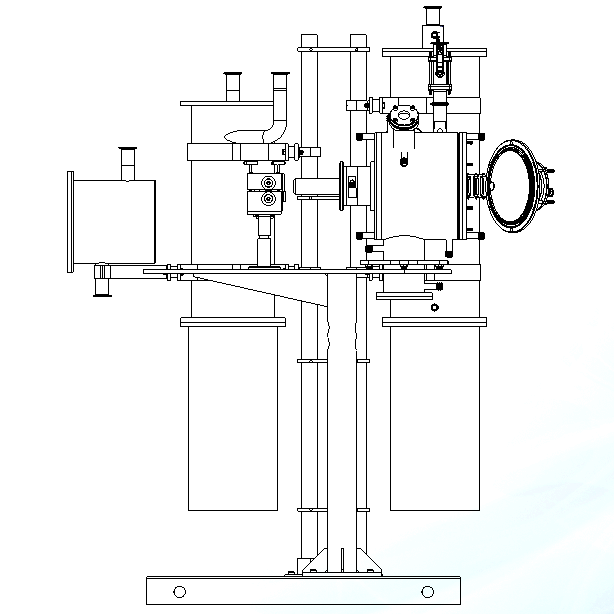

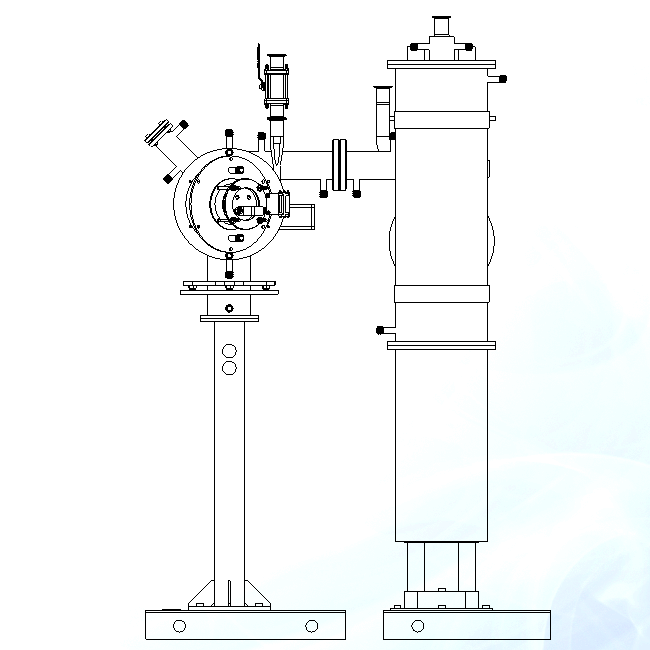

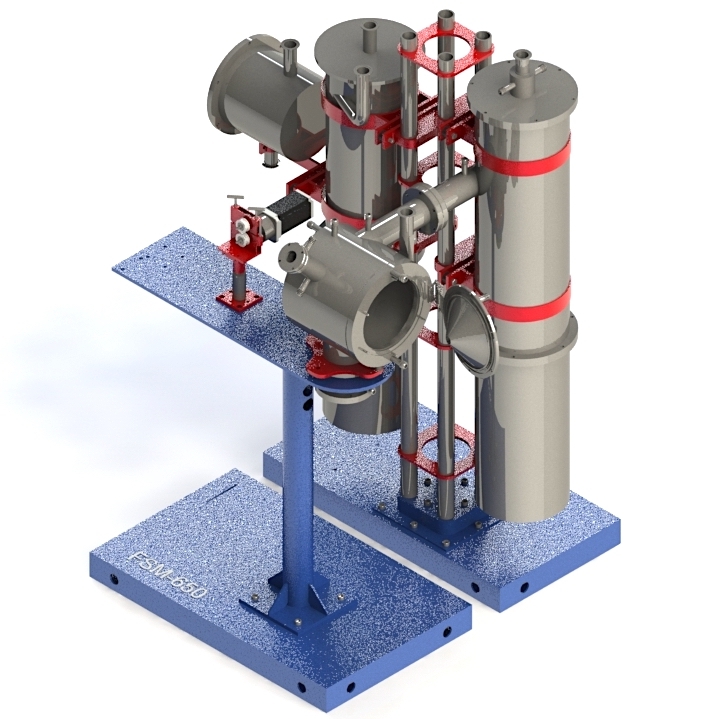

REACTOR FSM-650

FSM-650 characteristics:

Weight - 630 kg.

Assembled size - 1600x2000x2300 mm.

Electricity power - 23 kW.

Refrigerant volume - 1.5 cmh.

The volume of helium per cycle is 1.2-1.7 liters.

The amount of the product received per shift is 650-700 grams.

Weight - 630 kg.

Assembled size - 1600x2000x2300 mm.

Electricity power - 23 kW.

Refrigerant volume - 1.5 cmh.

The volume of helium per cycle is 1.2-1.7 liters.

The amount of the product received per shift is 650-700 grams.

Machine for the production of carbon black FSM-650.

It is a unique complex for the cyclic production of carbon black in an inert gas environment-helium or argon.

The capacity of the standard equipment of the FSM-650 installation is 650-700 grams of soot per day.

The continuous operation period of the unit is 22-24 hours.

The number of personnel involved in the production of carbon black – 2 operators.

The complex for the production of carbon black FSM-650, is a new generation installation. Advanced, multifunctional and highly efficient in the production mode of carbon black with a high content of nanomaterials. In contrast to the FSM-500 and FSM-500 VS, the FSM-650 machine has completely redesigned the gas dynamic flow distribution technology, improved the cooling system for both the hot zones of carbon black synthesis and the helium circulating in the system.

Comparing the FSM-500 VS and FSM-650 installations, a number of production and economic improvements can be identified:

- higher processing speed of graphite electrodes

- increased carbon black production

- more reliable and intuitive remote control interface

- significantly improved cooling system of the complex

- improved filtration system

Comparing the FSM-500 VS and FSM-650 installations, a number of production and economic improvements can be identified:

- higher processing speed of graphite electrodes

- increased carbon black production

- more reliable and intuitive remote control interface

- significantly improved cooling system of the complex

- improved filtration system

BRIEF DESCRIPTION OF THE FSM-650 MACHINE

Processability

Easy maintenance

Reliability

Product quality

Production Speed

Easy maintenance

Reliability

Product quality

Production Speed

MODEL COMPARISON

This complex partially repeats the schematics of the FSM-500 machine, but has significant technological features that allow for an order of magnitude improvement in production performance and reduce the cost of the main production.

The cooling system of the complex is provided with an additional pump for increasing the pressure in the refrigerant line-2.8 cubic meters / hour, which eliminates possible overheating of individual circuits of the complex and improves the quality of carbon black production processes. In the basic version, the FSM-650 complex is equipped with an overheating protection system for the main body of the reactor chamber, as well as an overheating prevention system.

The arc control system and quantitative adjustment of the ampere characteristic is also implemented in the basic version of the complex; the power supply unit of the installation has a mechanical reverse polarity system, which greatly simplifies and accelerates the process of carbon black production. Automatic reverse polarity reversal can be included in the complex as an option.

The unit is made of high-quality stainless steel with a sheet thickness of 2.1 to 2.5 mm. (depending on the structural element), in compliance with the basic conditions of production of equipment operating under pressure. Each unit of equipment is tested for the average vacuum level and the refrigerant pressure in the cooling systems up to 3.5 Atm.

The technological features of the installation, as an option, suggest the possibility of removing the control panel from the carbon black production area, by installing a video surveillance system and remote control of the electrode supply system.

The cooling system of the complex is provided with an additional pump for increasing the pressure in the refrigerant line-2.8 cubic meters / hour, which eliminates possible overheating of individual circuits of the complex and improves the quality of carbon black production processes. In the basic version, the FSM-650 complex is equipped with an overheating protection system for the main body of the reactor chamber, as well as an overheating prevention system.

The arc control system and quantitative adjustment of the ampere characteristic is also implemented in the basic version of the complex; the power supply unit of the installation has a mechanical reverse polarity system, which greatly simplifies and accelerates the process of carbon black production. Automatic reverse polarity reversal can be included in the complex as an option.

The unit is made of high-quality stainless steel with a sheet thickness of 2.1 to 2.5 mm. (depending on the structural element), in compliance with the basic conditions of production of equipment operating under pressure. Each unit of equipment is tested for the average vacuum level and the refrigerant pressure in the cooling systems up to 3.5 Atm.

The technological features of the installation, as an option, suggest the possibility of removing the control panel from the carbon black production area, by installing a video surveillance system and remote control of the electrode supply system.