Nanodispersed carbon black is formed during the burning of an electric arc between two graphite rods-the anode and the cathode in the carbon synthesis chamber of the FSM reactor. During the combustion process, the anode is vaporized and a fine soot with a high content of nanoparticles is formed from it. In this process cycle, the cathode is fixed and the anode is continuously fed at a constant / variable speed into the combustion chamber by a feed mechanism to control the required gap between the electrodes.

The work of the arc (graphite electrodes) takes place in the atmosphere of a gas circulating in a closed loop – helium, which transports the fine dust formed in the combustion chamber – soot to the receiver tanks. The helium circulation is provided by a continuously operating blower, the speed of which directly depends on the carbon black production cycle and the state of loading of the tanks of the receivers of the complex.

BRIEF DESCRIPTION OF THE FSM MACHINE OPERATION

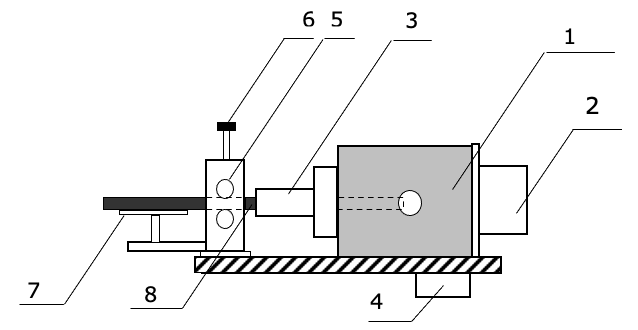

1 – the combustion chamber of

the reactor FSM

2 – cathode current collector

3 – electrode insertion chamber

4 – deposit collection

5 – anode feed mechanism

6 – locking screw

7 – anode current collector

8 – anode (graphite electrode)

the reactor FSM

2 – cathode current collector

3 – electrode insertion chamber

4 – deposit collection

5 – anode feed mechanism

6 – locking screw

7 – anode current collector

8 – anode (graphite electrode)

COMBUSTION CHAMBER (SYNTHESIS) THE REACTOR AND THE FEED MECHANISM

The attachment of the feeding mechanism to the base allows you to adjust its position in relation to the combustion chamber (carbon black synthesis) in the event of a misalignment.

The combustion chamber is a hollow metal cylinder with a cooling system along all the contours, between which the coolant flows during operation. On both sides, special cooled flanges (anode and cathode current collectors) are attached to the cylinder through rubber seals and textolite insulators, in which the contacts of the current collectors are located. The anode current collector has an electrode insertion chamber, on both sides of which special seals are installed that seal the combustion chamber (carbon black synthesis) when the anode is moved. The cathode current collector is mounted on hinges, which allows you to open it after removing the fasteners.

The combustion chamber is a hollow metal cylinder with a cooling system along all the contours, between which the coolant flows during operation. On both sides, special cooled flanges (anode and cathode current collectors) are attached to the cylinder through rubber seals and textolite insulators, in which the contacts of the current collectors are located. The anode current collector has an electrode insertion chamber, on both sides of which special seals are installed that seal the combustion chamber (carbon black synthesis) when the anode is moved. The cathode current collector is mounted on hinges, which allows you to open it after removing the fasteners.

The supply mechanism of the graphite electrode (anode) and the combustion chamber (carbon black synthesis) are installed strictly coaxially, because if this condition is not met during the movement of the anode, it may break or jam.

The feed mechanism consists of two metal rubberized rollers. The outer diameter of the rubber has a special profile in the form of notches, for clamping the anode.

The lower roller is the leading one, and the upper one is the driven one, and a gear motor is coaxially attached to it through the coupling, which provides rotation with the necessary force.

The feed mechanism consists of two metal rubberized rollers. The outer diameter of the rubber has a special profile in the form of notches, for clamping the anode.

The lower roller is the leading one, and the upper one is the driven one, and a gear motor is coaxially attached to it through the coupling, which provides rotation with the necessary force.

VACUUM PREPARATION OF FSM MACHINE

Vacuuming of the working area of the equipment is the main and fundamental stage of preparing the plant for the standard cycle of carbon black production. The removal of oxygen is not only due to achieving a stable arc in the production process, but also an indicator of the synthesis of a high-quality product-soot.

Before starting work, the internal surfaces of the FSM machine must be degreased and cleaned of foreign materials, such as:

- moisture

- oil

- fats of solvents and technical liquids

- soot residue

- garbage

High-quality preparation of the plant for launch-vacuuming, allows you to achieve from 25% to 40% of the quality result directly embedded in the finished product. The remaining moisture and loosely tightened flange mechanisms will not allow you to achieve a high content of the main substance in the soot, moreover, these omissions can lead to significant breakdowns and unexpected emergency shutdown of the equipment complex.

Vacuum preparation of the FSM machine is carried out in several stages – preliminary vacuuming and final vacuuming. During preliminary vacuuming process, the installation operator determines the stability of the equipment and the fixation of the tightened flange mechanisms; the final vacuuming allows you to determine the presence of hidden defects and breakdowns that can affect the operation and resource capacity of the equipment.

Before starting work, the internal surfaces of the FSM machine must be degreased and cleaned of foreign materials, such as:

- moisture

- oil

- fats of solvents and technical liquids

- soot residue

- garbage

High-quality preparation of the plant for launch-vacuuming, allows you to achieve from 25% to 40% of the quality result directly embedded in the finished product. The remaining moisture and loosely tightened flange mechanisms will not allow you to achieve a high content of the main substance in the soot, moreover, these omissions can lead to significant breakdowns and unexpected emergency shutdown of the equipment complex.

Vacuum preparation of the FSM machine is carried out in several stages – preliminary vacuuming and final vacuuming. During preliminary vacuuming process, the installation operator determines the stability of the equipment and the fixation of the tightened flange mechanisms; the final vacuuming allows you to determine the presence of hidden defects and breakdowns that can affect the operation and resource capacity of the equipment.

SCHEMATIC DIAGRAM OF CARBON BLACK PRODUCTION

Process flow for production of nanodispersed carbon black powder, which is the accumulation of dump the rest of subsistence of the material, but in the same time raw materials for production of other forms of carbon, including nanocarbon allotropic forms.

RAW MATERIALS

ROD GRAPHITE

ATMOSPHERE

HELIUM GAS

SYNTHESIS OF

PROCESS

PROCESS

CARBON BLACK PRODUCTION

COOLING DOWN

COOLING DOWN

CATHODE DEPOSIT

NANOMATERIALS MIX:

NANOTUBES

ASTRALINES

FULLERITES

NANOTUBES

ASTRALINES

FULLERITES

SECONDARY PRODUCT

CARBON BLACK

CARBON BLACK - FULLERENE SOOT

MAIN PRODUCT

EXTRACTION

CYCLE

CYCLE

MIX

FULLERENE

FULLERENE

O-XYLENE

O-XYLENE

CARBON BLACK POWDER -

LAUNDERED

LAUNDERED

FULLERENE

SOOT - EMPTY

SOOT - EMPTY

SECONDARY PRODUCT

TECHNICAL CARBON BLACK

INDIVIDUAL FULLERENE C60

O-XYLENE

O-XYLENE

SORBENT

ACTIVATED CARBON

MAIN PRODUCT

SORBENT - ACTIVATED CARBON

ENRICHED ACTIVATED

CARBON - MIX FULLERENE C60/C70

CARBON - MIX FULLERENE C60/C70

SECONDARY PRODUCT

COOLING DOWN

COOLING DOWN

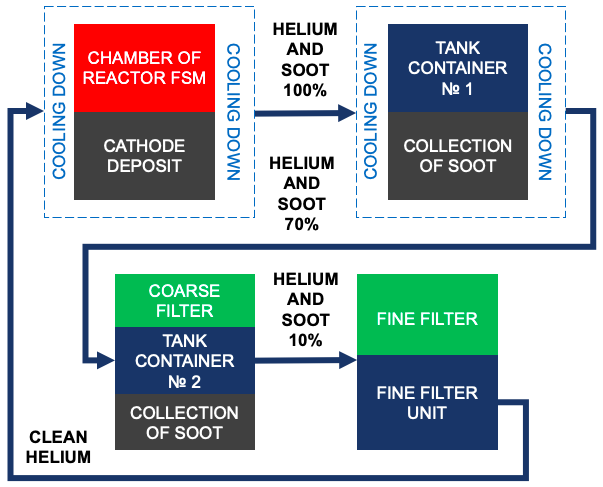

SYSTEM FINISHED PRODUCT COLLECTION AND FILTRATION

Tank-container No. 1 and Tank-container No. 2 are vertically mounted metal cylinders with removable dust collectors located in the lower part. Tank-container No. 1 is water-cooled.

The coarse strainer installed in the tank-container No. 2 is also a metal cylinder mounted horizontally and having a much shorter length than the tank-containers. Inside it is fixed a cylinder, the walls of which are several layers of fine mesh. The strainer has a removable flange.

The coarse strainer installed in the tank-container No. 2 is also a metal cylinder mounted horizontally and having a much shorter length than the tank-containers. Inside it is fixed a cylinder, the walls of which are several layers of fine mesh. The strainer has a removable flange.

CHAMBER OF REACTOR FSM

CATHODE

DEPOSIT

DEPOSIT

TANK CONTAINER № 1

COLLECTION OF SOOT

COARSE FILTER

COLLECTION OF SOOT

COOLING DOWN

COOLING DOWN

TANK CONTAINER № 2

FINE FILTER

FINE FILTER UNIT

HELIUM AND SOOT 100%

HELIUM AND SOOT 70%

HELIUM AND SOOT 10%

CLEAN HELIUM

Most of the soot carried out by helium from the chamber settles in the lower part (soot collectors) of tank-container No. 1; a much smaller part of the soot settles in tank-container No. 2 and a small part settles in the fine filter.

The process of formation of carbon black occurs in the combustion chamber. In the current collectors, graphite rods are installed on both sides of the chamber, which are the electrodes-the cathode and the anode.

The cathode is fixed, and the anode can be moved along the axis of the chamber. During the operation of the FSM Machine, an electric arc burns between the electrodes and the anode turns into fine carbon black (soot), which contains 10-12% of the main mass of the main substance – carbon of the allotropic form.

When burning, the anode is shortened, and to maintain the continuity of the process, it is necessary to constantly supply it to the arc zone to avoid interrupting the process of carbon black production. This function is performed by the rod feed mechanism, moving the anode along the axis of the chamber at a constant speed. The soot formed in the chamber is removed by a stream of helium into the tank containers and filters connected in series.

The cathode is fixed, and the anode can be moved along the axis of the chamber. During the operation of the FSM Machine, an electric arc burns between the electrodes and the anode turns into fine carbon black (soot), which contains 10-12% of the main mass of the main substance – carbon of the allotropic form.

When burning, the anode is shortened, and to maintain the continuity of the process, it is necessary to constantly supply it to the arc zone to avoid interrupting the process of carbon black production. This function is performed by the rod feed mechanism, moving the anode along the axis of the chamber at a constant speed. The soot formed in the chamber is removed by a stream of helium into the tank containers and filters connected in series.

REACTOR COMBUSTION CHAMBER AND FEED MECHANISM

The equipment of the FSM line for the production of carbon black is primarily projected for technical specialists and operators, namely, ease of operation and maintenance.

An intuitive system for preparing equipment for operation, the process of carbon synthesis, automatic supply of electrodes to the synthesis chamber that does not require constant monitoring and a simple system for unloading the finished product put FSM machines on a par with the best analogues.

The technological features and construction of the equipment are developed taking into account the margin for the duration of work in the process of carbon synthesis, as well as the margin of safety at the moments of abnormal – emergency overheating of the complex.

An intuitive system for preparing equipment for operation, the process of carbon synthesis, automatic supply of electrodes to the synthesis chamber that does not require constant monitoring and a simple system for unloading the finished product put FSM machines on a par with the best analogues.

The technological features and construction of the equipment are developed taking into account the margin for the duration of work in the process of carbon synthesis, as well as the margin of safety at the moments of abnormal – emergency overheating of the complex.

SPECIFICS OF FSM MACHINES