A vacuum system is a set of engineering solutions, technologies and groups of various kinds of aggregates in one technological scheme that allows them to interact during the workflow cycle. This type of system qualitatively copes with the creation of an increased vacuum level in any technological device. Also, with the help of vacuum systems, it is possible to quickly pump out or degass vessels and vacuum water pipes, which for such systems is not at all a visible problem. Vacuum systems can cope with such tasks that will definitely be impossible to perform under standard conditions for standard systems operating on an ordinary standard operating principle.

The very concept of a vacuum system implies the presence of a wide range of different vacuum units, which can have a variety of characteristics, design types and operating principles. No modern and technological enterprise today can do without vacuum technologies and vacuum units, since vacuum systems now show excellent performance in terms of performance, and the efficiency of such devices is so high that it surpasses all other systems in all possible indicators several times. When comparing standard systems with vacuum systems, it becomes immediately clear that vacuum units, due to their manufacturability, have a number of significant advantages, so most buyers choose this type of systems.

VACUUM SYSTEMS: TECHNOLOGIES, EQUIPMENT, APPLICATION

VACUUM SYSTEM

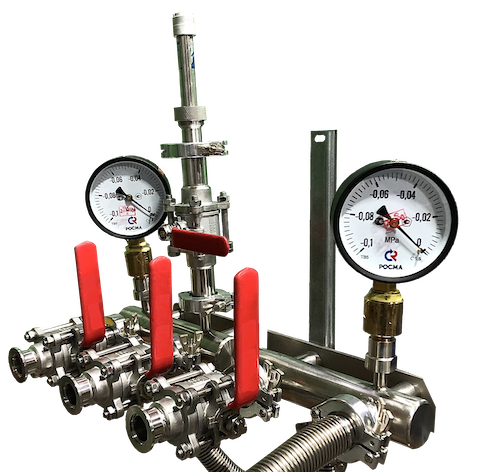

APPEARANCE OF THE VACUUM SYSTEM

When a company purchases an aggregate for money equal to standard systems, it receives a technological, high-quality, modern and functional device that has a number of significant advantages that often make themselves felt during operation. Do not forget about the many additional functions that are present in vacuum systems. At first glance, it may seem that all these functions do not play any significant role, but in fact their importance in the operation process is very significant and if these additions are used correctly, it is possible to significantly increase labor productivity, production output and reduce production costs.

The price of such vacuum systems is currently very high, and an ordinary person is unlikely to be able to afford such a large unit with such a range of possibilities. It is because of this that such systems are most often used in large enterprises, where such systems can perform a number of time-consuming tasks that are not something difficult for such a large and productive system that is capable of performing more difficult tasks.

It is also necessary to consider the quality of the equipment, which may not always be productive in terms of power, but its reliability will be high. It is necessary to carefully approach the choice of units and assemblies of vacuum systems, in order to exclude subsequent problems with operational and production parameters.

When a company purchases an aggregate for money equal to standard systems, it receives a technological, high-quality, modern and functional device that has a number of significant advantages that often make themselves felt during operation. Do not forget about the many additional functions that are present in vacuum systems. At first glance, it may seem that all these functions do not play any significant role, but in fact their importance in the operation process is very significant and if these additions are used correctly, it is possible to significantly increase labor productivity, production output and reduce production costs.

The price of such vacuum systems is currently very high, and an ordinary person is unlikely to be able to afford such a large unit with such a range of possibilities. It is because of this that such systems are most often used in large enterprises, where such systems can perform a number of time-consuming tasks that are not something difficult for such a large and productive system that is capable of performing more difficult tasks.

It is also necessary to consider the quality of the equipment, which may not always be productive in terms of power, but its reliability will be high. It is necessary to carefully approach the choice of units and assemblies of vacuum systems, in order to exclude subsequent problems with operational and production parameters.

VACUUM INSTALLATION

A vacuum installation is a complexly assembled system that is created on the principle of combining several pumps, receivers, vacuum sensors, mains and fittings, which in turn create and maintain the required level of technical vacuum. All this happens during the pumping of air or gas mixtures. Most often, such installations are used in stationary systems, but there are also multiple exceptions in terms of transportation complexes, since recently such installations have often been used in a variety of fields:

- oil fields

- gas production

- and other geological exploration activities.

Most often, such systems can be seen in manufacturing organizations that are more than interested in the operation of such a device.

As for the scope of application, it is quite wide for this equipment and already now such vacuum systems are used in a variety of fields, including even the most non-standard options.

A vacuum installation is a complexly assembled system that is created on the principle of combining several pumps, receivers, vacuum sensors, mains and fittings, which in turn create and maintain the required level of technical vacuum. All this happens during the pumping of air or gas mixtures. Most often, such installations are used in stationary systems, but there are also multiple exceptions in terms of transportation complexes, since recently such installations have often been used in a variety of fields:

- oil fields

- gas production

- and other geological exploration activities.

Most often, such systems can be seen in manufacturing organizations that are more than interested in the operation of such a device.

As for the scope of application, it is quite wide for this equipment and already now such vacuum systems are used in a variety of fields, including even the most non-standard options.

VACUUM INSTALLATION

FITTINGS FLANGE SENSORS

VACUUM TECHNOLOGY

VACUUM PUMP

The main areas of application of vacuum installations:

- Chemical

- Food

- Textile

- Pharmaceutical

- Automotive

- Metallurgical

Each of these spheres has its own characteristic features, which is not so often found in the modern world. So if a company chooses a device for a wide application, then it should concentrate on vacuum installations, since it can show excellent performance in terms of performance, quality and reliability in general.

A good advantage of such systems is also the possibility of spraying, which at the moment is a promising technology and is very popular in the market. Such processing of materials is now one of the highest priorities in terms of quality; the cost of this option is high – but the goal justifies the means, and many are willing to pay for it. The spraying process itself is not as complicated as it may seem at first glance, and in order for it to work effectively, it is necessary to find a technological and suitable vacuum installation in accordance with the main parameters exactly as indicated in the instructions for the operation of the spraying equipment.

VACUUM SYSTEM EQUIPMENT

If we talk about the equipment and equipment complex of the vacuum system, then various vacuum flanges, vacuum fittings, vacuum sensors, pumping equipment and vacuum equipment control systems are included here; each element of which is a very important node, and carries a technological meaning.

The main elements of the vacuum system:

- The vacuum unit is the main element of the entire system, which produces either air pumping or spraying of materials on various products

- Pumping post — this part of the vacuum system performs pumping and filling of various components of the equipment

- A vacuum line is an element that conducts through itself all the gas that enters the vacuum system itself

- The vacuum installation is the basis of the entire system, on which its operation is actually based.

- Chemical

- Food

- Textile

- Pharmaceutical

- Automotive

- Metallurgical

Each of these spheres has its own characteristic features, which is not so often found in the modern world. So if a company chooses a device for a wide application, then it should concentrate on vacuum installations, since it can show excellent performance in terms of performance, quality and reliability in general.

A good advantage of such systems is also the possibility of spraying, which at the moment is a promising technology and is very popular in the market. Such processing of materials is now one of the highest priorities in terms of quality; the cost of this option is high – but the goal justifies the means, and many are willing to pay for it. The spraying process itself is not as complicated as it may seem at first glance, and in order for it to work effectively, it is necessary to find a technological and suitable vacuum installation in accordance with the main parameters exactly as indicated in the instructions for the operation of the spraying equipment.

VACUUM SYSTEM EQUIPMENT

If we talk about the equipment and equipment complex of the vacuum system, then various vacuum flanges, vacuum fittings, vacuum sensors, pumping equipment and vacuum equipment control systems are included here; each element of which is a very important node, and carries a technological meaning.

The main elements of the vacuum system:

- The vacuum unit is the main element of the entire system, which produces either air pumping or spraying of materials on various products

- Pumping post — this part of the vacuum system performs pumping and filling of various components of the equipment

- A vacuum line is an element that conducts through itself all the gas that enters the vacuum system itself

- The vacuum installation is the basis of the entire system, on which its operation is actually based.

Technological vacuum systems are also equipped with modern standard and non-standard components and mechanisms:

- Flanges are the connecting elements of the system that guide the unit itself to perform certain tasks

- Vacuum fittings are also an equally important part of the system, the elements of which take on the role of balancing the entire unit and its performance indicators

- Vacuum sensors — this category of elements serves as a kind of indicator, thanks to which it is possible to track the condition of a particular volume of equipment.

The indicators themselves , according to their principle of operation , are divided into three main categories:

- Ionization

- Thermal

- Deformation

Each of these indicators is designed to perform separate tasks, since there are quite a lot of them in any version of the equipment and each of the parameters must be clearly controlled by the operators servicing the equipment.

- Flanges are the connecting elements of the system that guide the unit itself to perform certain tasks

- Vacuum fittings are also an equally important part of the system, the elements of which take on the role of balancing the entire unit and its performance indicators

- Vacuum sensors — this category of elements serves as a kind of indicator, thanks to which it is possible to track the condition of a particular volume of equipment.

The indicators themselves , according to their principle of operation , are divided into three main categories:

- Ionization

- Thermal

- Deformation

Each of these indicators is designed to perform separate tasks, since there are quite a lot of them in any version of the equipment and each of the parameters must be clearly controlled by the operators servicing the equipment.

VACUUM TECHNOLOGY

Vacuum technology is primarily designed to create and maintain a certain level of vacuum in technological equipment. As we know, vacuum is one of the key parts of the operation of any vacuum equipment, since if there is a high or ultra-high vacuum in the system, it can produce high performance indicators in terms of profile production. This is a key point in vacuum systems and vacuum technology, which is only becoming more obvious every year. The range of vacuum equipment is really very wide and among the total number of units, any company can find something that suits it.

Vacuum technology also shows the qualitative and quantitative intensity of the flow of physico-chemical processes, which is why many companies are moving from standard solutions to more functional and productive ones. There is always a certain amount of free space inside the entire vacuum equipment, which is created due to the action of the system. This space allows you to exclude the effect of gases on certain processes, which is also one of the advantages of this system.

The technique of creating a vacuum in these units is actually quite interesting, since it is created with the help of several elements of the system that actively interact with each other and are able to form a high or even ultra-high vacuum. But do not forget about maintaining vacuum conditions, as its creation is far from the only process in the system. The set and maintenance of vacuum in vacuum technology is one of its advantages, since such equipment has proven itself perfectly in this matter, and is able to maintain a high vacuum level for a long time. This allows the equipment to operate normally for a long time and provide stable performance indicators during the production of the product.

Many manufacturers have paid attention to this type of equipment precisely because of such capabilities, and at the moment this equipment is leading in popularity. A significant role in this is played by a wide range of applications of this equipment, as they can be used in a variety of fields and in each of them it is able to show itself exclusively with the best production performance.

Vacuum technology is primarily designed to create and maintain a certain level of vacuum in technological equipment. As we know, vacuum is one of the key parts of the operation of any vacuum equipment, since if there is a high or ultra-high vacuum in the system, it can produce high performance indicators in terms of profile production. This is a key point in vacuum systems and vacuum technology, which is only becoming more obvious every year. The range of vacuum equipment is really very wide and among the total number of units, any company can find something that suits it.

Vacuum technology also shows the qualitative and quantitative intensity of the flow of physico-chemical processes, which is why many companies are moving from standard solutions to more functional and productive ones. There is always a certain amount of free space inside the entire vacuum equipment, which is created due to the action of the system. This space allows you to exclude the effect of gases on certain processes, which is also one of the advantages of this system.

The technique of creating a vacuum in these units is actually quite interesting, since it is created with the help of several elements of the system that actively interact with each other and are able to form a high or even ultra-high vacuum. But do not forget about maintaining vacuum conditions, as its creation is far from the only process in the system. The set and maintenance of vacuum in vacuum technology is one of its advantages, since such equipment has proven itself perfectly in this matter, and is able to maintain a high vacuum level for a long time. This allows the equipment to operate normally for a long time and provide stable performance indicators during the production of the product.

Many manufacturers have paid attention to this type of equipment precisely because of such capabilities, and at the moment this equipment is leading in popularity. A significant role in this is played by a wide range of applications of this equipment, as they can be used in a variety of fields and in each of them it is able to show itself exclusively with the best production performance.

VACUUM PUMPS

A vacuum pump is a technologically advanced and precision mechanism that is capable of simultaneously performing a number of technological processes, which is why it is very popular.

Let's analyze the basic principles of operation of vacuum pumps and auxiliary mechanisms. Initially, there is a change in the volume of the crescent-shaped blades, which lead to the fact that the gas moves throughout the interior of the unit. As for the cavities themselves, they begin to work thanks to two spirals, which, thanks to their unusual structure, create optimal conditions for this. At the same time, it is worth noting that only one of the spirals is in motion, while the second one is in the same position all the time, in fact, without performing any functions.

If we touch on the topic of the use of vacuum pumps, then you can learn a lot of interesting features of this type of units. At the moment, there are a large number of enterprises on the market that buy vacuum pumps for permanent operation, since their price is not so high, while the efficiency during operation reaches the highest quality characteristics, which, in fact, attracts the attention of consumers.

A vacuum pump is a technologically advanced and precision mechanism that is capable of simultaneously performing a number of technological processes, which is why it is very popular.

Let's analyze the basic principles of operation of vacuum pumps and auxiliary mechanisms. Initially, there is a change in the volume of the crescent-shaped blades, which lead to the fact that the gas moves throughout the interior of the unit. As for the cavities themselves, they begin to work thanks to two spirals, which, thanks to their unusual structure, create optimal conditions for this. At the same time, it is worth noting that only one of the spirals is in motion, while the second one is in the same position all the time, in fact, without performing any functions.

If we touch on the topic of the use of vacuum pumps, then you can learn a lot of interesting features of this type of units. At the moment, there are a large number of enterprises on the market that buy vacuum pumps for permanent operation, since their price is not so high, while the efficiency during operation reaches the highest quality characteristics, which, in fact, attracts the attention of consumers.

Areas of application of vacuum pumps:

- Vacuum drying

- Degassing process

- Distillation of liquid inside vacuum

- Furnaces of vacuum principle of operation

- Refrigeration equipment designed for cooling

This is not the whole list of areas where vacuum pumps are actively used, since there are still separate areas of other industries where such units have found their wide application.

Also do not forget that vacuum pumps are divided into certain types and types, so that it is easier for a potential consumer to classify them under their own tasks and choose the device that is needed for the required technological process.

Types of vacuum pumps:

- Booster type pump

- Cryogenic pump

- Pre-vacuum pump

- Water ring pump

- Rotary vane pump

- Turbomolecular pump

All these types of vacuum pumps are aimed at performing individual and specific tasks that, one way or another, are important to any enterprise. Vacuum pumps are already used in a wide variety of industries, and some pump models perform far from the most direct functions there. But there are other areas where vacuum pumps are actively used, which are valued for their manufacturability, resource and productivity.

ABSTRACTS OF THE TOPIC:

vacuum system; vacuum system circuit; vacuum system price; vacuum system operating principle; vacuum system drives; vacuum system calculation; automatic vacuum system; vacuum system sensor; vacuum system elements; vacuum system materials; vacuum system equipment; centralized vacuum system; industrial vacuum systems; central vacuum system; production of vacuum systems; vacuum transport systems; vacuum degassing systems; vacuum pressing systems; characteristics of vacuum systems; vacuum system maintenance; automated vacuum systems; vacuum system tester; laboratory vacuum system; leak detectors of vacuum systems; medical vacuum systems; vacuum bag pressing system; design of vacuum systems; classification and types of vacuum systems; detection of air leakage into the vacuum system; fittings for vacuum systems; vacuum compressor systems; vacuum systems for obtaining graphite nanostructures; vacuum system pressure tester; system for vacuum forming and degassing; components of vacuum systems; vacuum arc systems for obtaining graphite nanostructures; heating elements for vacuum systems; drawings of vacuum systems.

- Vacuum drying

- Degassing process

- Distillation of liquid inside vacuum

- Furnaces of vacuum principle of operation

- Refrigeration equipment designed for cooling

This is not the whole list of areas where vacuum pumps are actively used, since there are still separate areas of other industries where such units have found their wide application.

Also do not forget that vacuum pumps are divided into certain types and types, so that it is easier for a potential consumer to classify them under their own tasks and choose the device that is needed for the required technological process.

Types of vacuum pumps:

- Booster type pump

- Cryogenic pump

- Pre-vacuum pump

- Water ring pump

- Rotary vane pump

- Turbomolecular pump

All these types of vacuum pumps are aimed at performing individual and specific tasks that, one way or another, are important to any enterprise. Vacuum pumps are already used in a wide variety of industries, and some pump models perform far from the most direct functions there. But there are other areas where vacuum pumps are actively used, which are valued for their manufacturability, resource and productivity.

ABSTRACTS OF THE TOPIC:

vacuum system; vacuum system circuit; vacuum system price; vacuum system operating principle; vacuum system drives; vacuum system calculation; automatic vacuum system; vacuum system sensor; vacuum system elements; vacuum system materials; vacuum system equipment; centralized vacuum system; industrial vacuum systems; central vacuum system; production of vacuum systems; vacuum transport systems; vacuum degassing systems; vacuum pressing systems; characteristics of vacuum systems; vacuum system maintenance; automated vacuum systems; vacuum system tester; laboratory vacuum system; leak detectors of vacuum systems; medical vacuum systems; vacuum bag pressing system; design of vacuum systems; classification and types of vacuum systems; detection of air leakage into the vacuum system; fittings for vacuum systems; vacuum compressor systems; vacuum systems for obtaining graphite nanostructures; vacuum system pressure tester; system for vacuum forming and degassing; components of vacuum systems; vacuum arc systems for obtaining graphite nanostructures; heating elements for vacuum systems; drawings of vacuum systems.