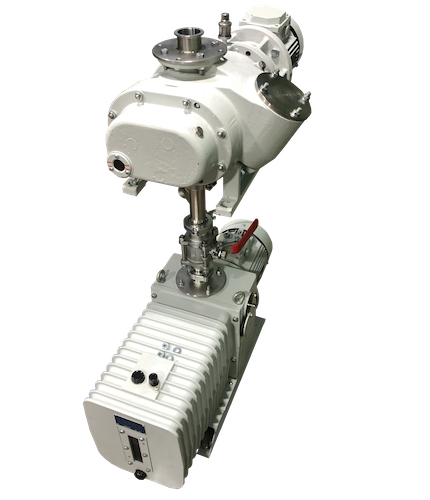

For a faster and better degassing process of the main working volume of the FSM machine, the equipment complex is equipped with a vacuum station consisting of a series-connected pre-vacuum pump and a booster-type blower.

This pump unit significantly speeds up the process of preparing the equipment for start-up, reducing the idle time of the FSM machine without work and reducing the periods of unloading the equipment. It can operate continuously at an inlet pressure of no more than 133 Pa or pumping out one or more sealed vessels with a total volume of 3.5 m3 from atmospheric to the maximum residual pressure for 8 hours.

The vacuum station is connected to the FSM machine through a sealed vacuum line that allows it to withstand a vacuum depth of -2. 5x10 (-3). A ball valve or a pneumatic gate valve is installed on the outlet part of the main line, which allows isolating the vacuum station from the main working volume of the FSM machine at the right time.

To increase the service life of the vacuum station, a fine air filter is also installed on the water main, which cuts off fine particles of carbon black, as well as production products.

VACUUM STATION (OPTIONAL)