During the production of carbon black-fullerene-containing soot, the synthesis product obtained in the reactor chamber, due to the gas-dynamic flows of inert helium gas, is moved to the storage collectors - tank-containers, and remains there until the equipment is completely stopped.

Each piece of equipment from the entire FSM line for the production of carbon black has two tank-containers. Each of them has a specific function during the operation of the equipment, allowing you to prolong the soot production process and improve its quality.

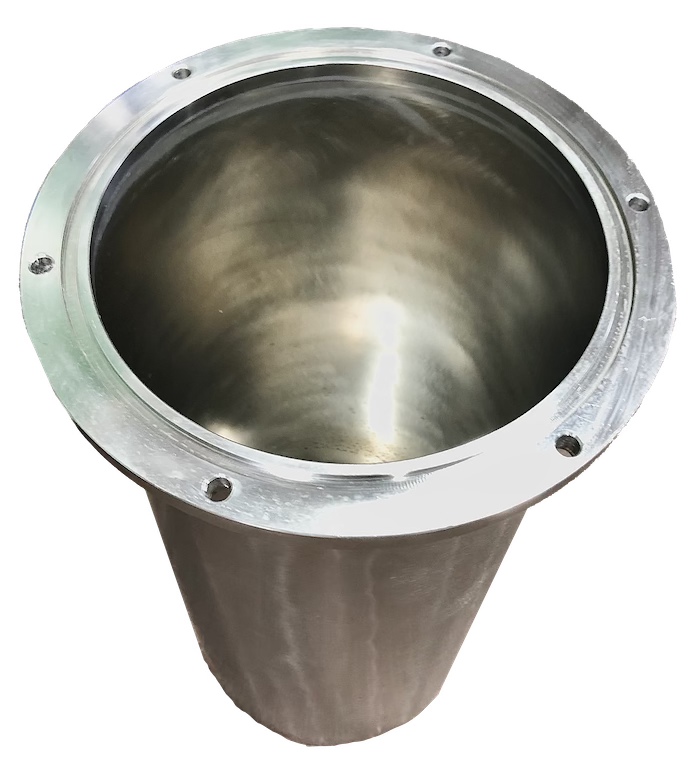

The tank-container is completely made of stainless steel with a thickness of at least 1.5 mm. The quality of metal processing does not allow a porous and worn surface, which makes it easier to clean the equipment from soot at the time of its unloading.

Processing of the flange connection of the element, fully complies with the ISO standard. The pressure surface of the tank-container flanges has a groove for installing a vacuum gasket (such as silicone or viton) for faster achievement of the parameters required for the operation of the equipment.

Options for attaching tank containers to the cases of storage collectors are made by bolting or clamp KF-250.

TANK-CONTAINER