The FULLERENE SOOT MACHINE - FSM is equipped with two types of vacuum measuring device - switch-mechanical for the primary (operational) determination of the vacuum value, and digital (electronic) for determining the dynamic vacuum at the stage of preparing the installation for launch.

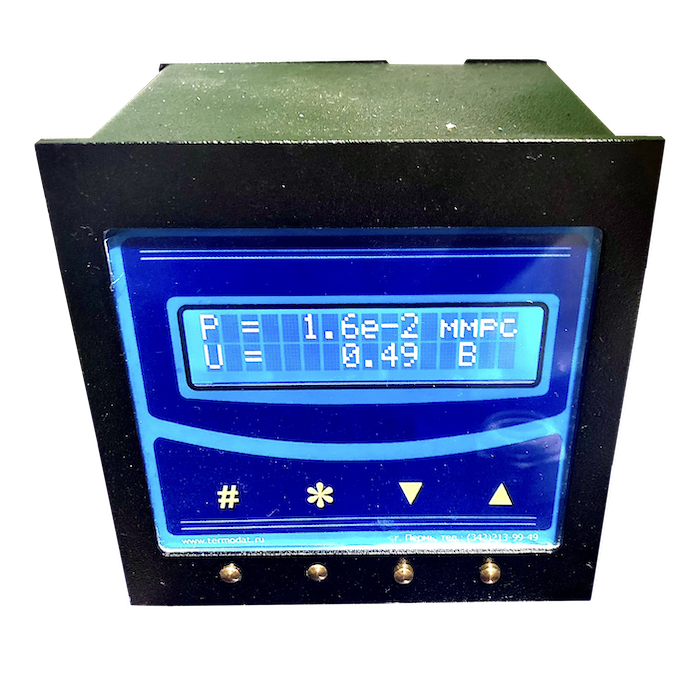

A digital (electronic vacuum measuring device) shows the current values of the medium in the general gas dynamic system FSM and is a control device that informs the operator of the installation about the correctness of the production process of vacuuming.

One digital electronic vacuum measuring device (digital monitoring device) with a metal sensor is installed on the FSM gas distribution ramp, designed to measure vacuum depth values up to 5.0x10 (-4). This vacuum measuring device is intended only for measuring the vacuum values at the stage of preparing the FSM for start. The vacuum gauge sensor is equipped with a KF-25 flap to exclude it from the main gas-dynamic system during the production of carbon black; this flap allows you to save the reference settings of the sensor, as well as to exclude possible damage to the measuring mechanism.

At the stage of preparing the FSM for launch, provided that the pre-vacuum pump and the booster type blower are operating in the range of values necessary for starting, as well as the KF-25 open flap, the vacuum measuring device can show a value in the range from 3.7 x 10 (-2) to 5.3 x 10 (-3).

ELECTRONIC VACUUM MEASURING DEVICE

The digital vacuum gauge sensor or thermistor pressure gauge converter is designed to work as part of vacuum measuring device and vacuum sensors.

The primary heat sensor converts the pressure value into an electrical signal.

Vacuum measuring device of this class, due to the simplicity of the device of the converters, are the most common devices for measuring the average vacuum, in particular for monitoring the pre-dilution in vacuum systems. The effect of thermal vacuum measuring device is based on the dependence of the thermal conductivity of rarefied gases on the gas concentration (and, consequently, on the pressure).

The main element of a thermal pressure converter is a conductor (heater) heated by passing current, according to a change in the temperature of which (or by a change in the electrical power consumed to maintain a constant temperature) they judge the pressure. According to the method of temperature control, thermal vacuum measuring device are divided into thermocouples, in which the pressure measure is the thermo of a thermocouple connected to a heater, and into resistance vacuum measuring device, where the temperature dependence of the electric resistance of the heater is used. In some devices (for example, string ones), the temperature elongation of the heater is used.

The primary heat sensor converts the pressure value into an electrical signal.

Vacuum measuring device of this class, due to the simplicity of the device of the converters, are the most common devices for measuring the average vacuum, in particular for monitoring the pre-dilution in vacuum systems. The effect of thermal vacuum measuring device is based on the dependence of the thermal conductivity of rarefied gases on the gas concentration (and, consequently, on the pressure).

The main element of a thermal pressure converter is a conductor (heater) heated by passing current, according to a change in the temperature of which (or by a change in the electrical power consumed to maintain a constant temperature) they judge the pressure. According to the method of temperature control, thermal vacuum measuring device are divided into thermocouples, in which the pressure measure is the thermo of a thermocouple connected to a heater, and into resistance vacuum measuring device, where the temperature dependence of the electric resistance of the heater is used. In some devices (for example, string ones), the temperature elongation of the heater is used.

ELECTRONIC VACUUM MEASURING DEVICE SENSOR

The readings of thermal vacuum meters depend on the type of gas; this dependence is especially pronounced at pressures above 100 Pa. Fluctuations in the ambient temperature can also distort the measurement results. Typical calibration characteristics are given for an external temperature of + 20°C. The temperature error of thermocouple converters is less than that of resistance converters; the latter are more common in automated installations due to a higher output signal level and less inertia.

Calibration of the sensor.

Calibration is performed by installing the sensor on the connecting flange of the pump type NVR-5DM through the intermediate valve KF-25. The KF-25 flap is set to the OPEN position. Before starting the pump, the values and parameters of the device and the sensor are reset in the menu of the digital vacuum monitoring device, the device menu is displayed on the main screen of digital values and readings of the atmosphere. The pump is being started. After reaching the pump's passport values and fixing them on the device screen, the KF-25 is switched to the CLOSED position, the pump is switched off – the sensor has been calibrated.

Calibration of the sensor.

Calibration is performed by installing the sensor on the connecting flange of the pump type NVR-5DM through the intermediate valve KF-25. The KF-25 flap is set to the OPEN position. Before starting the pump, the values and parameters of the device and the sensor are reset in the menu of the digital vacuum monitoring device, the device menu is displayed on the main screen of digital values and readings of the atmosphere. The pump is being started. After reaching the pump's passport values and fixing them on the device screen, the KF-25 is switched to the CLOSED position, the pump is switched off – the sensor has been calibrated.