Copper graphite brushes are special electrically conductive parts of the FSM machine, which make a sliding contact between a movable graphite electrode and a stationary current collector, and serve to supply current.

Specifically for the production technology of carbon black, an individual solution has been developed in the form of a ratio of copper base and graphite filler forming a monolithic, wear-resistant and temperature-resistant material. This product is a physical deterioration element of the current collector construction, depending on the quality of operation and the technical qualification of the operator of the FSM machine, the brushes can operate up to 60 -70 full working cycles.

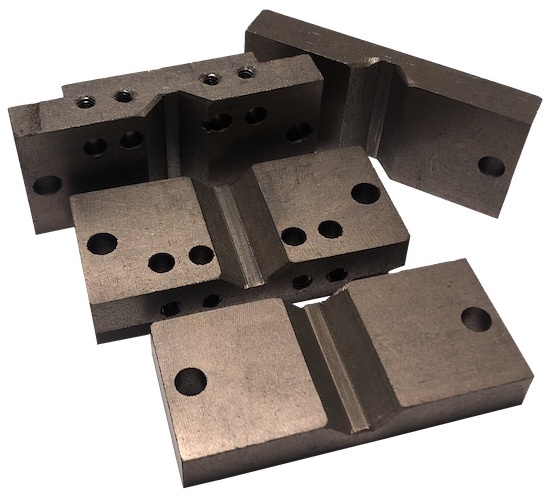

The copper graphite brushes of the FSM machine current collector are divided into two types:

- lower brush – support (static)

- upper brush – pressure (dynamic)

The lower current collector is a guide, which in turn gives a double load on this element, reducing its resource capacity.

COPPER GRAPHITE BRUSHES - TERMINAL CURRENT CONDUCTORS

Additionally:

With the constant operation of the FSM machine, copper-graphite brushes require special attention and maintenance. Periodic cleaning of the anode and cathode current collector unit, checking the surface fit and friction in the assembly, as well as the quality of the clamping mechanism. In case of loosening of the clamping mechanism of the current collector brushes, their maintenance is required:

- strengthening of the pulling of the clamping screws

- replacement of the clamping mechanism elements.

The composition of copper-graphite brushes in the ratio of copper and graphite should be balanced. If the amount of copper in the ratio of these two components is higher than normal, then the brush will collapse during prolonged heating, which in turn will lower the contact spot of the brush and the graphite electrode and lead to a complete stop of the carbon black synthesis process. In the case when the amount of graphite in the ratio of components is higher than normal, the structural element will be brittle and less resistant to mechanical loads, such as:

- strengthening of the pulling of the clamping screws

- passage of the graphite electrode

- structural stability of the product at high temperature values.

The balanced ratio of copper and graphite in this element will increase the qualitative and quantitative indicators of the FSM machine in the process of carbon black production.

With the constant operation of the FSM machine, copper-graphite brushes require special attention and maintenance. Periodic cleaning of the anode and cathode current collector unit, checking the surface fit and friction in the assembly, as well as the quality of the clamping mechanism. In case of loosening of the clamping mechanism of the current collector brushes, their maintenance is required:

- strengthening of the pulling of the clamping screws

- replacement of the clamping mechanism elements.

The composition of copper-graphite brushes in the ratio of copper and graphite should be balanced. If the amount of copper in the ratio of these two components is higher than normal, then the brush will collapse during prolonged heating, which in turn will lower the contact spot of the brush and the graphite electrode and lead to a complete stop of the carbon black synthesis process. In the case when the amount of graphite in the ratio of components is higher than normal, the structural element will be brittle and less resistant to mechanical loads, such as:

- strengthening of the pulling of the clamping screws

- passage of the graphite electrode

- structural stability of the product at high temperature values.

The balanced ratio of copper and graphite in this element will increase the qualitative and quantitative indicators of the FSM machine in the process of carbon black production.